-

Envoyez-nous un courriel

sale@lscmagnetics.com -

Numéro de contact

+86 -13559234186

Envoyez-nous un courriel

sale@lscmagnetics.com

Numéro de contact

+86 -13559234186

Types d'ancrages de levage et leurs applications dans la construction préfabriquée

Oct 28, 2025Dans le secteur de la construction moderne, la technologie des bâtiments préfabriqués révolutionne les méthodes de construction traditionnelles grâce à ses avantages : haute efficacité, respect de l’environnement et qualité maîtrisée. Lors de la production, du transport et de l’installation des éléments préfabriqués, l’importance des systèmes de levage et d’ancrage, éléments clés assurant la liaison entre les composants et les engins de levage, est indéniable. Bien plus que de simples connecteurs, ils garantissent la sécurité de l’ensemble du composant en supportant son poids.

Définition et fonction d'un Ancre de levage

Un point d'ancrage de levage est un ancrage mécanique pré-scellé dans une structure en béton, conçu spécifiquement pour le levage. Il fonctionne avec un dispositif de levage (embrayage, anneau, manille, etc.) pour former un point de levage temporaire amovible. Ses principales fonctions sont les suivantes :

Transmettre en toute sécurité la force de levage à la structure en béton ;

Prévenir les dommages localisés tels que le fendillement et l'écaillage des bords lors du levage ;

Permettant un accrochage et un décrochage rapides, améliorant ainsi l'efficacité opérationnelle des grues à tour ou des grues mobiles ;

Répondre aux exigences complexes de charge liées à de multiples opérations de retournement (démoulage, retournement et repositionnement sur site).

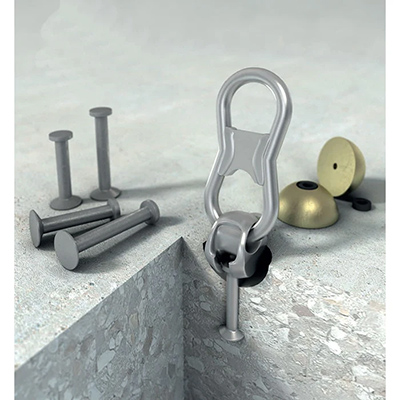

Un système d'ancrage de levage typique se compose généralement de trois éléments :

Tige d'ancrage : La partie encastrée dans le béton, généralement munie d'un crochet, d'un fil ou d'une queue de forme spéciale (comme une forme ondulée) pour assurer une adhérence maximale au béton et empêcher l'arrachement.

Partie exposée : La structure utilisée pour connecter le dispositif de levage, qui peut être un œillet, un trou fileté ou une rotule.

Dispositif de levage : Composant utilisé avec le point d’ancrage de levage, tel qu’une manille ou une élingue spécialisée, relié entre le crochet de la grue et le point d’ancrage.

Voici les types et caractéristiques des ancrages de levage couramment utilisés dans les éléments préfabriqués.

Construction : Acier rond avec une tête sphérique forgée à une extrémité et un pied d'ancrage ou une tige droite à l'autre ; utilisé avec un embrayage de levage.

Avantages :

Rotation et oscillation à 360° pour s'adapter à la tension diagonale ;

Faible profondeur d'ancrage, adaptée aux panneaux à parois minces ;

Verrouillage automatique de l'embrayage ; l'installation et le retrait ne prennent que quelques secondes.

Plage de charge : 1,3–32 t.

Applications : Composants généraux tels que les escaliers, les panneaux muraux extérieurs, les colonnes et les poutres, particulièrement adaptés aux applications de tension diagonale ou d'inclinaison.

2. Douille filetée/ancrage de pied

Construction : Douille à paroi épaisse avec un pied d'ancrage inférieur (ou une queue ondulée), filetage intérieur pour la connexion par boulon à œil.

Avantages :

Le point de levage est au même niveau que la surface du béton, ce qui donne un aspect propre ;

Les boulons remplaçables peuvent être réutilisés à plusieurs reprises ;

Propriétés de cisaillement et de traction équilibrées. Plage de charge : 0,5–20 t.

Applications : Éléments nécessitant une esthétique soignée, tels que les murs extérieurs en béton apparent, les panneaux décoratifs et les toitures de galeries tubulaires.

3. Ancre à double tête

Construction : Une tige d'ancrage unique avec extrémités forgées et équipée d'un embrayage à double point.

Avantages : Application de la charge en deux points, déformation hors plan minimale et retournement plus doux.

Applications : Retournement d'éléments minces tels que de grandes dalles de plancher et des tabliers de pont creux.

Construction : L'extrémité inférieure de la tige d'ancre s'évase en forme de « queue d'hirondelle » ou de « queue de poisson ».

Avantages : Répartition de la charge, réduisant le risque de fissuration aux bords des parois minces.

Applications : Marches d'escalier, garde-corps de balcon et carreaux décoratifs préfabriqués d'une épaisseur inférieure à 80 mm.

5. Ancre à queue ondulée

Construction : La tige d’ancrage est pliée en plusieurs sections en forme ondulée, ce qui augmente la longueur d’ancrage. Avantages : Offre une résistance à l’arrachement élevée sans nécessiter d’ancrages supplémentaires ; convient aux bétons de faible résistance en phase de prise.

Applications : Composants nécessitant un démoulage rapide, tels que les couloirs de tuyauterie, les ponceaux et les poutres à parois minces.

6. Ancrage à disque (disque QuikLift®)

Construction : Tige courte + disque de grand diamètre. Utilisé pour les panneaux extérieurs des murs isolants sandwich.

Avantages : Levage en un seul point sans perforer la couche isolante ; le disque offre une large surface d'appui.

Applications : Levage des panneaux extérieurs des murs sandwich préfabriqués isolés pour éviter les ponts thermiques.

7. Ancrage à goupille

Construction : Broche ronde simple + tête d'adaptateur amovible avec un trou conique.

Avantages : Faible coût ; la tête de l’adaptateur est recyclable ; après démontage, il ne reste qu’un petit trou conique, ce qui facilite la réparation.

Applications : Composants soumis à des charges faibles à moyennes, tels que les pipelines, les ponceaux et les bordures de trottoir.

Le choix et l'utilisation des points d'ancrage de levage ne sont pas arbitraires et nécessitent une réflexion approfondie :

Charge de travail : Le poids de la pièce à soulever.

Facteur dynamique : Effets des charges dynamiques dues aux démarrages et arrêts brusques lors du levage. Ce facteur est généralement multiplié par un coefficient de sécurité (par exemple, 1,5 ou plus) calculé à partir de la charge statique.

Résistance du béton : La résistance du béton est généralement faible lors du démoulage, et il est essentiel de s'assurer qu'il est suffisamment résistant pour supporter les forces de levage.

Angle de levage : L’angle entre les élingues augmente considérablement la charge réelle sur la tige d’ancrage ; 60 degrés est un angle courant et recommandé.

Facteur de sécurité : L'ancrage de levage est conçu avec un facteur de sécurité élevé (généralement ≥3 pour le matériau lui-même et ≥2,5 pour la rupture du cône en béton) afin de garantir un levage sûr et fiable.

Forme et centre de gravité des composants : le nombre et l’emplacement des points d’ancrage doivent être calculés pour assurer un levage équilibré.