-

Envoyez-nous un courriel

sale@lscmagnetics.com -

Numéro de contact

+86 -13559234186

Envoyez-nous un courriel

sale@lscmagnetics.com

Numéro de contact

+86 -13559234186

Déferriseur magnétique permanent : une « collision amicale » avec les pièces d'usure, obtenant un équilibre parfait entre haute efficacité et douceur

Oct 14, 2025Dans la vaste chaîne de production industrielle, l'enlèvement du fer, bien qu'il ne s'agisse que d'une petite étape, est crucial pour la qualité des produits, la sécurité des équipements et l'efficacité de la production. Les méthodes traditionnelles d'enlèvement du fer, notamment celles qui reposent sur la transmission de puissance, impliquent souvent des impacts violents sur le matériau, l'équipement lui-même et même les processus en aval. Vibrations, frottements, impacts : ces termes sont courants dans les carnets de maintenance des consommables.

Cependant, avec l’application croissante de la technologie des aimants permanents, une révolution silencieuse est en train de se produire. Éliminateurs de fer à aimant permanentGrâce à leur principe de fonctionnement unique, les robots s'engagent dans une « collision amicale » sans précédent avec des pièces consommables. Il ne s'agit pas d'une véritable collision physique, mais plutôt d'une innovation technologique qui remplace le « dur » par le « doux ».

I. Qu'est-ce qu'une collision « inamicale » ? La tragédie des déferriseurs traditionnels

Avant d'aborder le terme « convivial », il faut d'abord comprendre ce que signifie « inamical ». Les déferriseurs électromagnétiques traditionnels, ou certains dispositifs mécaniques, présentent souvent les inconvénients suivants :

A. Consommation continue d’énergie et production de chaleur : Fer électromagnétique Les extracteurs nécessitent une alimentation électrique continue pour maintenir une force magnétique élevée. Les bobines génèrent de la chaleur au fil du temps, et les matériaux isolants internes, comme les fils, sont des pièces intrinsèquement vulnérables. Les températures élevées accélèrent leur vieillissement et peuvent même les brûler.

B. Systèmes de refroidissement complexes : Les déferriseurs électromagnétiques haute puissance nécessitent souvent des systèmes de refroidissement par huile ou par air. Ce système comprend de nombreux composants, tels que des pompes à huile, des tuyauteries et des joints. La défaillance de l'un de ces composants peut entraîner des arrêts de production et des coûts de maintenance élevés.

C. Impact et usure lors du déferrisation : Que ce soit par raclage à bande ou par enlèvement mécanique, le processus de déchargement génère une friction et un impact intenses entre les débris ferreux et la bande de déchargement, les rouleaux et les racleurs. Les bandes peuvent s'user, les racleurs peuvent s'émousser et les roulements peuvent être endommagés ; autant de pièces vulnérables nécessitant un remplacement fréquent. D. Interférence avec les matériaux : Certaines méthodes de déferrisation à haute puissance peuvent provoquer des cassures ou générer de la poussière sur les matériaux délicats ou fragiles (tels que les aliments, les matières premières chimiques et les granulés de plastique), affectant ainsi la qualité du produit.

Ces interactions « hostiles » se traduisent en fin de compte par des coûts d’exploitation plus élevés, des temps d’arrêt plus fréquents et une charge de gestion plus complexe.

II. Séparateurs magnétiques permanents : le secret de la convivialité

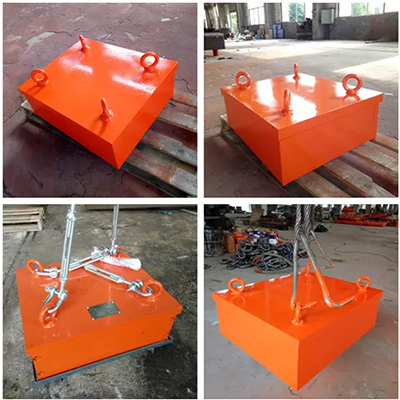

Le principal avantage des séparateurs magnétiques permanents réside dans leur philosophie d'inaction. Ils utilisent des aimants permanents à base de terres rares haute performance (comme le NdFeB) pour générer une force magnétique puissante et permanente, sans nécessiter de source d'énergie externe. Cette résistance intrinsèque est à la base de leur convivialité.

A. Système énergétique respectueux : zéro consommation, zéro production de chaleur

Les séparateurs magnétiques permanents fonctionnent sans électricité. Cela signifie :

* Élimination des consommables : Les points de défaillance potentiels et les consommables, tels que les bobines, les matériaux isolants et les systèmes de refroidissement, sont entièrement supprimés de la conception. Cela simplifie considérablement la structure de l'équipement.

* Fiabilité accrue : sans composants susceptibles de brûler et sans fuite de liquide de refroidissement, l'équipement peut fonctionner de manière stable dans des environnements difficiles (tels que les environnements poussiéreux et humides), prolongeant considérablement sa durée de vie.

* Coûts d’exploitation considérablement réduits : les factures d’électricité sont réduites à zéro, tandis que les coûts associés à l’entretien du système de refroidissement sont également éliminés.

B. « Respectueux de sa structure » : extrêmement simple, solide comme un roc

Les séparateurs magnétiques permanents présentent généralement une structure très simple, composée principalement du système magnétique et du boîtier. Ils ne comportent ni pièces rotatives ni mécanismes de transmission complexes.

* Réduction significative du nombre de pièces d'usure mécaniques : Les pièces d'usure mécaniques traditionnelles telles que les roulements, les engrenages, les courroies et les moteurs sont quasiment inexistantes. Cela minimise naturellement les taux de défaillance des équipements.

* Entretien extrêmement faible : l'entretien quotidien se limite généralement à une simple inspection et à un nettoyage de surface, éliminant ainsi les tâches fastidieuses de remplacement des courroies et de réglage de la tension.

C. « Amical » pour le processus de déchargement : surmonter la dureté par la douceur

Il s'agit de la manifestation la plus directe de la « collision amicale ». Pour les séparateurs magnétiques permanents à déchargement manuel ou semi-automatique, les opérateurs utilisent simplement un racleur non magnétique pour éliminer facilement le fer adsorbé. Ce procédé est contrôlable et flexible, évitant les chocs violents et les frottements associés au déchargement forcé.

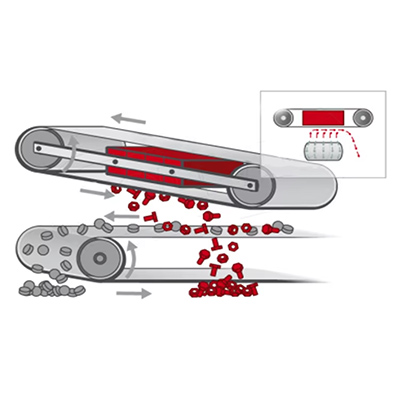

Le processus de déferrisation des déferriseurs magnétiques permanents entièrement automatiques a également été optimisé. Utilisant soit une séparation par champ magnétique, soit une méthode de raclage simple, ces méthodes sont plus douces et usent beaucoup moins la bande racleuse et l'équipement que les méthodes traditionnelles.

D. Respectueux des matériaux et des processus : Silent Guardian

Ne nécessitant aucun composant puissant, les déferriseurs magnétiques permanents fonctionnent pratiquement sans vibrations ni bruit. Ils flottent silencieusement au-dessus de la chaîne de convoyage, agissant comme un gardien silencieux, capturant avec précision les impuretés ferreuses sans perturber le flux délicat des matériaux, garantissant ainsi leur intégrité et un environnement de production propre.

III. La valeur fondamentale de cette « collision amicale »

Transformer « hostile » en « amical » crée une valeur tangible :

* Réduction des coûts et amélioration de l'efficacité : permet d'économiser de l'électricité, de réduire les stocks de pièces de rechange et de réduire les coûts de main-d'œuvre et de temps de maintenance, ce qui entraîne des améliorations globales de la rentabilité globale.

* Amélioration de l'efficacité globale de l'équipement (OEE) : moins de pannes et de temps d'arrêt signifient une meilleure utilisation de l'équipement et une capacité de production garantie.

* Sécurité et protection de l'environnement : Pas de fuites de chaleur ou d'huile, créant un environnement de travail plus sûr ; le fonctionnement à énergie zéro s'aligne sur les concepts de fabrication verte et de développement durable.

* Retour sur investissement élevé : bien que le coût d’achat initial puisse être légèrement plus élevé, les faibles coûts d’exploitation et de maintenance tout au long du cycle de vie garantissent un retour sur investissement à long terme très impressionnant.

Cette « collision amicale » entre les déferriseurs magnétiques permanents et les pièces consommables constitue une véritable évolution technologique, remplaçant la force brute par une conception intelligente. Elle démontre que la protection la plus efficace ne requiert pas nécessairement une confrontation spectaculaire ; elle peut aussi résulter d'une attraction silencieuse et durable.

Lors du choix d'une solution de déferrisation, il est important de ne pas se limiter au prix et de prendre en compte l'ensemble du cycle de vie. Choisir un déferriseur magnétique permanent LSC, c'est s'engager à respecter votre ligne de production, votre équipe de maintenance et les résultats de votre entreprise.

ÉTIQUETTES :